It’s amazing how a brand can come onto the scene and explode within a matter of months, going from virtually being unknown (in the grand scheme of things) to becoming the talk of the industry. In a sense this happened to Saint Crispins a few years back. It’s not that they were “unknown” per se, but that the people that did know them were only a small fraction compared those that know them now. I always wonder how it happened? Was it because Leather Soul started stocking them? Was it because Leffot did? Who knows really. But I will say that there was a transition of power in the ranks at SC that may have had something to do with it. You see, the company was started way back when by Michael Rolling but then about 10-12 years ago, his cousin Phillip Car, joined the ranks. Not going into detail, I think that they had a difference in the way in which they wanted to take the company, so Michael set off on his own to start Zonkey Boot and Phillip was left in charge to turn SC into what it is today. And the rest is history…

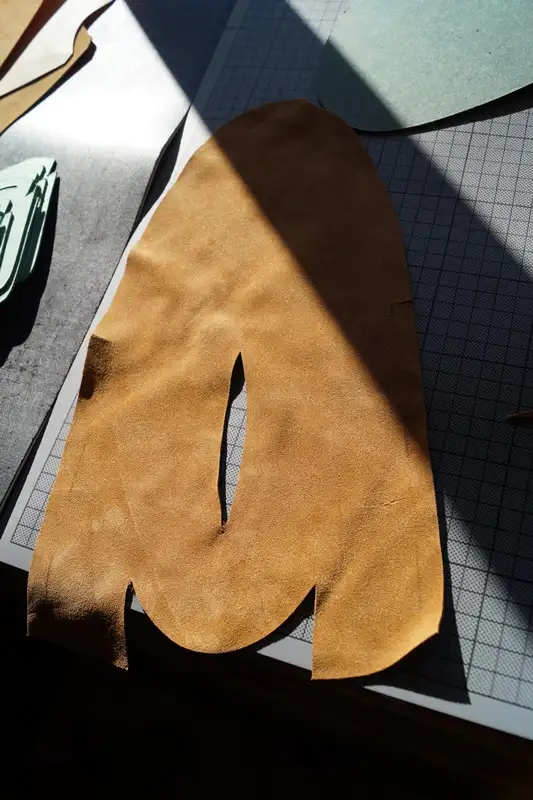

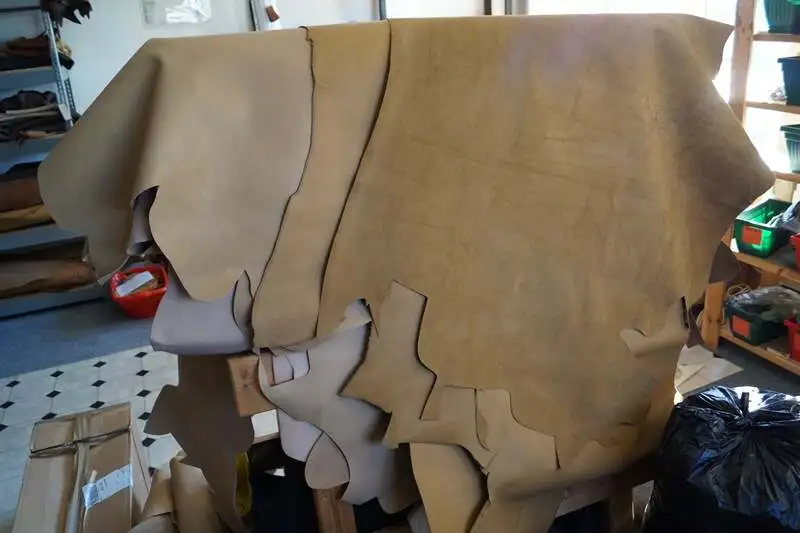

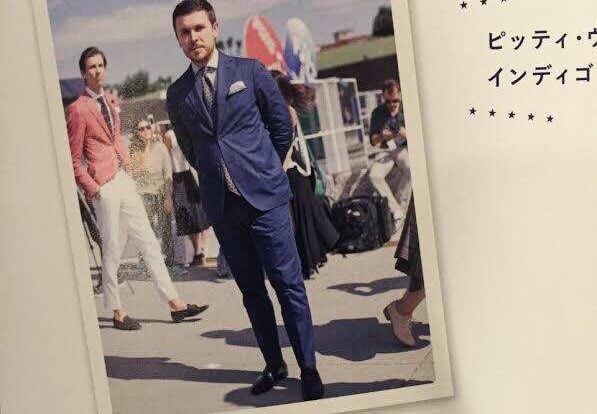

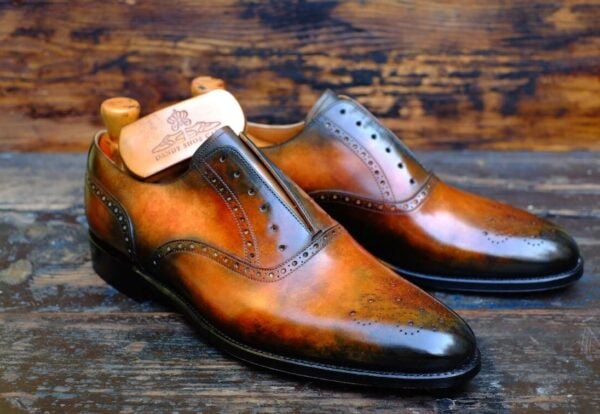

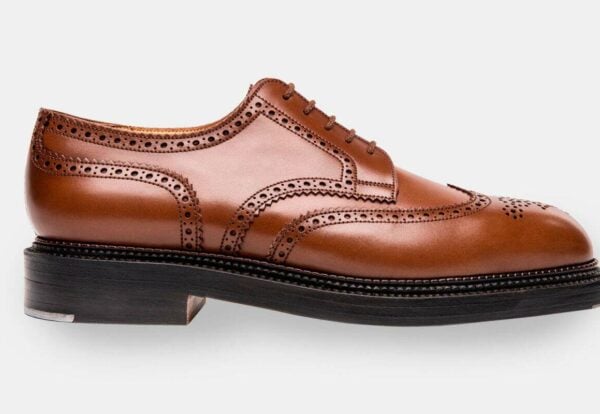

Fast forward to present day and let’s talk about who SC are today. In essence they are a company that makes shoes pretty much 95% by hand in a small factory in Romania (but the company is Austrian) using top grade leathers and craftsmanship and to be dead honest, produce some of the finest shoes known to man. They have positioned themselves as a MTO type of company as each shoe is really made one at a time. There is not some grand production line. It is a pair by pair operation which allows people to customize their shoes to quite an extent and virtually get what they want without having to pay your typical upcharge that most ‘factory brands’ impose. This, I believe, has been a huge part of their success as people love the idea of customization and love even more that they don’t have to pay more for that customization.

On the flip side you have your skeptics, who say “are Romanian made shoes really worth those prices?” These are usually your European elitists who believe that good shoes can only be made from a handful of countries, not including Eastern Europe, which is quite a flawed mentality to have in my opinion. I will say, without saying who but I am sure that many of you can guess, that one of the top shoemakers in the world (and English) was very impressed with SC the first time that he saw a pair in person. From shoemaker to shoemaker, that is the top compliment someone could receive. And what I love about that, is that it just goes to prove the concept that good shoes can be made anywhere in the world. It is not about the country, nor the history, but about the passion of the people and the greatness of leadership from the owner of the brand. That is what makes good shoes, not origin nor anything else. Hard work, passion, attention to detail and good materials. And SC has all of those things!

So I was fortunate enough to be able to see the production process of Saint Crispins shoes and I must say that it was quite a nice set up. I have seen many workshops of bespoke makers, and larger factories, but never really a small in-between. And it was like the two of them put together to make a happy medium. Keep in mind that Saint Crispins only makes around 1500 pairs a year. That is about 6 pairs/day. So while it may seem like they are big, in reality they are still quite a relatively small company in terms of production. But when keeping quality high it is important to not try and do too much and I think that Phillip always has this in the back of his mind too. Biting off more than one can chew leads to other problems and quality tends to suffer because of it. So SC is happy with this output, so long as it does not decrease.

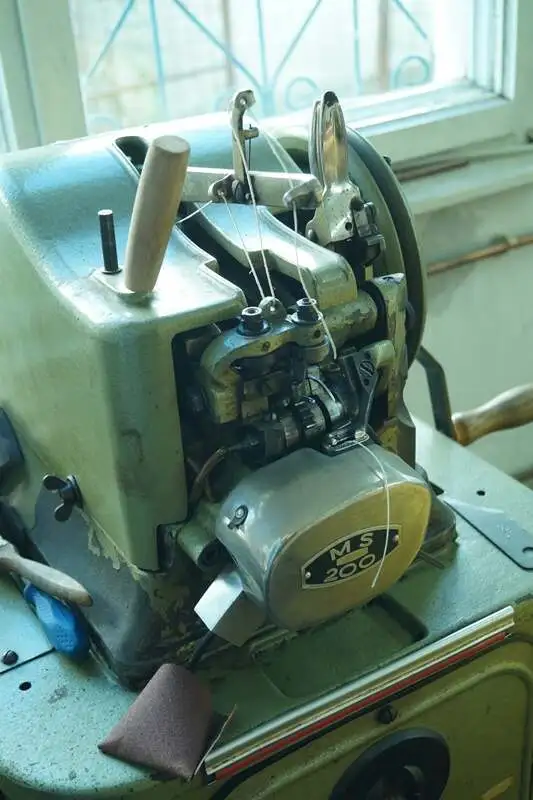

As I mentioned, the shoes about 95% handmade. That 5% is attaching the sole, which is done by a very old hand-driven machine that stitches on the sole. Phillip tells me that the results are nearly identical (providing that one is skilled with this very old-world machine), but the time to attach the sole is drastically reduced using the machine, so in his mind it only makes mathematical sense to do so. And presuming that he is accurate, I can’t say that I can disagree with that notion. And from what I have seen of their sole stitching, it looks quite tidy to me and I have never heard of sole separation before, so why not use it instead of doing it by hand?! However, funny enough, when they do a re-sole, it is done by hand and not using the machine.

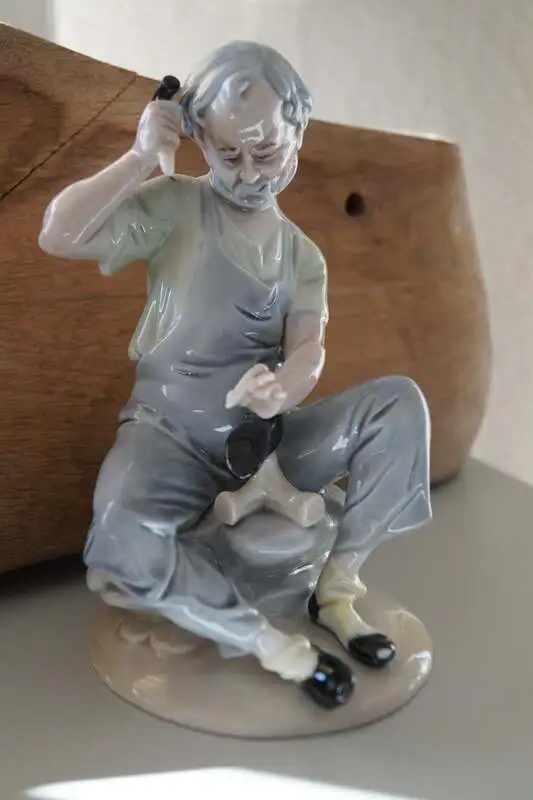

As you can see from the pictures, everything is very hands on and done in-house, from the shoe bags, to the shoe boxes, to the shoe laces and even the shoe trees. It’s quite impressive that they do it all. But for me that is the best way as it is all controlled to ensure that the quality of everything is down to the owner of the company. And if the owner of said company has high standards, then you can trust that when receiving their product, you will be getting the best of the best. And that is why even at €1250 per pair, their shoes are flying out the door like hot cakes. Because at the end of the day it is a good shoe for a good price and made by people who truly care about the quality of their product. And that is Saint Crispins for you….

Justin, I cannot begin to tell you how much I have been looking forward to this report, and how much I have enjoyed reading through and taking in all the terrific pictures. This clearly took a lot of time to put together and I very much appreciate the effort. I will confess to a near giddy admiration of and enthusiasm for this brand. I have had the pleasure of meeting (and being fitted for a customized last by) Mr. Car and count myself fortunate to own a few pairs of their exquisite shoes and boots. I am envious of your opportunity to visit there in person, but this pictorial account is surely the next best thing. Well done!

hey, great story. “loc pentru fumat” doesn’t mean “no smoking”, but quite the opposite actually: “smoking place”. This is where workers CAN smoke

Wow, I didn’t expect to see so very many pictures of the Saint Crispin’s workshop and shoes. Impressive and interesting. Lots of styles I like and many interesting details.

Mr. Justin, congratulations. Another great work of another great effort with other major e interesting jewel information from the world of well-made shoes lovers, one of the best houses in the world, made with very high quality and integrity. Thanks again!

How ironic that the internet is the root cause of the success of old world crafts by making such companies known to the world overnight and by linking the small community of like minded people and potential

Very detailed visit … Nice article