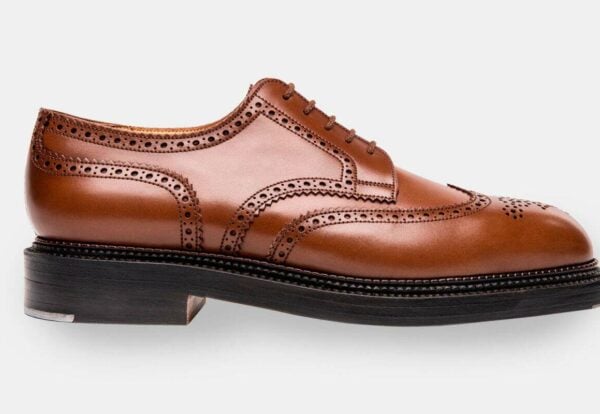

For those that may not have realized I was recently in Milan for a trip to Lineapelle, one of world’s biggest leather fairs, in the hopes to find some new suppliers. As someone who owns a shoe brand, I can say for everyone in the industry that leather, it’s consistency and availability is definitely among the biggest problems that we all face when it comes to running the business. There are probably more high end shoe brands today than ever before and if I am really going to be blunt and brutally honest, more outrageously demanding customers too. This means that we are all fighting for the best of it and it’s usually like anything in the world: the one with the biggest bank roll wins. That leaves small brands such as myself struggling to continuously get the good stuff as many of your reputable tanneries are supplying their big clients first, only to provide the leftovers to the small ones. And it’s a never-ending battle, but one that I am personally prepared to face. So I went on the quest to make a change.

It all came together quite nicely really as a few months back I had received an email from a representative of Ilcea just to inform me that they enjoyed the blog and were ready to provide me with any information that I ever needed regarding the tannery. A nice gesture for sure, but even better was the timing as I was hoping to make a change from one of the French Tanneries that I use to replace it with an Italian one. So we got to chatting which lead to me making a decision come to Lineapelle to meet them and even more so to have a factory tour of the Ilcea tannery, of which they were so kind to invite me to. So off I went.

A bit of background knowledge: Ilcea grew its popularity during the era of Ferragamo and when Salvatore was actually alive and building the brand. Ilcea at that point only supplied leather for women’s shoes and Ferragamo was their star client. With the way that Ferragamo’s name became synonymous with first class shoes, it was no surprise that Ilcea’s popularity sky rocketed from the supplying of their leather. Soon after that, all of the women’s brands were knocking on their door in the hopes to get some. But it was actually not until the 80’s that Ilcea starting making leather for men’s shoes, and while I cannot name their clients as per their request, I can tell you that some of the biggest brands in the high end shoe world (most of them in fact) are using Ilcea leather. But like most great stories, there was a bitter twist to the fate of Ilcea, one that left the company nearly in ruins.

Not long ago one of the 3 owners of Ilcea had died. He was the one that really ran the business and made it what it was. Shortly after one of the 2 remaining wanted out and sold his stock to the last one standing. However, this gentleman was the one who apparently cared the least for the company as he started to ruin it’s name by selling off old, crap leather and sourcing the cows (hides) from areas that are known for not raising them well (i.e. cheap). What came after that was substandard product and unhappy clients. Relationships that had gone on for 10-20 years were ruined in the blink of an eye and Ilcea quickly came crashing down. So, then of course like any businessman would do he sold off what was left and cleaned his hands of this problem. Word got round that Ilcea was for sale and a very reputable tannery from Florence (Tuscany really), called Gruppo Vecchia Toscana�who was known for making leather for accessories (bags, wallets, leather goods etc.) decided that venturing into the world of shoes just might be an interesting adventure. So they bought it in the hopes to restore it to its rightful glory as one of the great tanneries of the shoe industry.

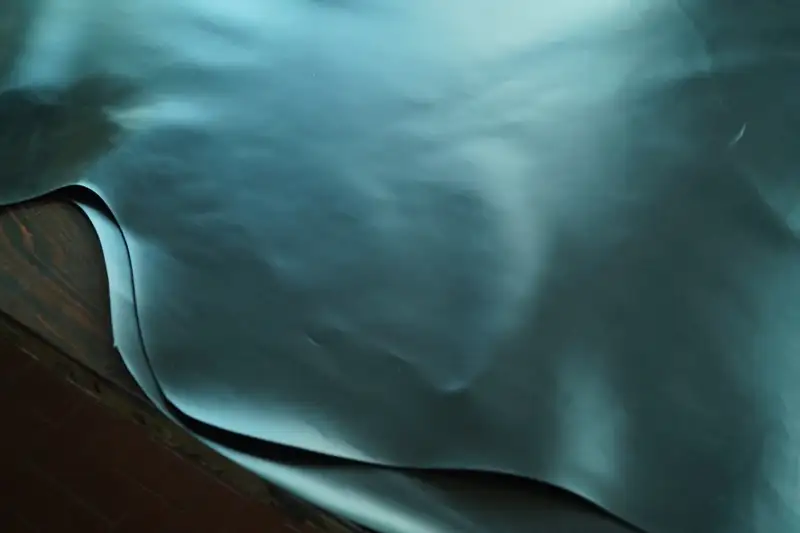

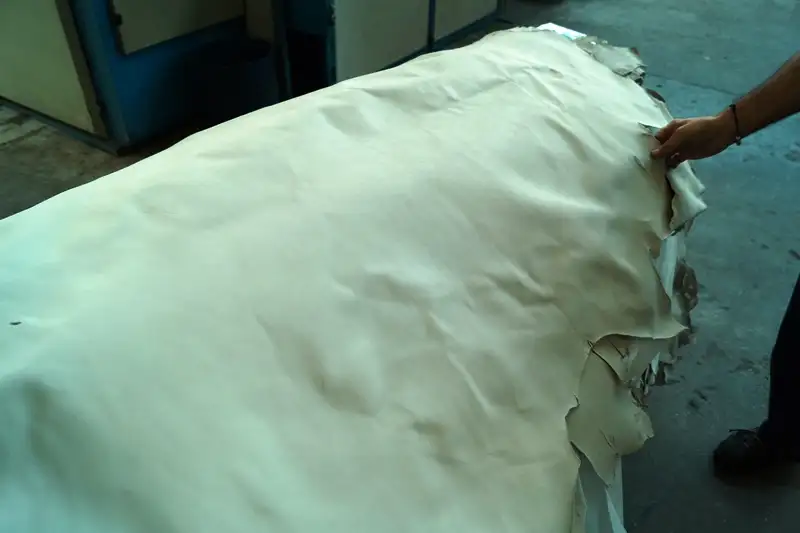

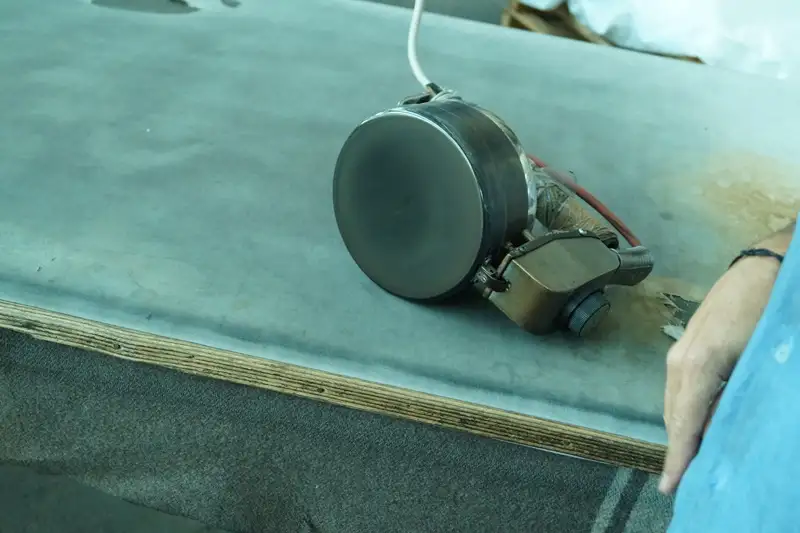

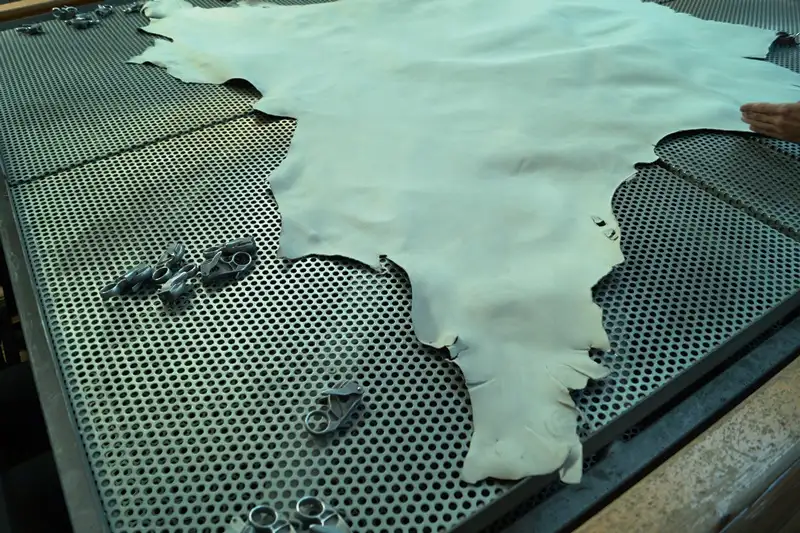

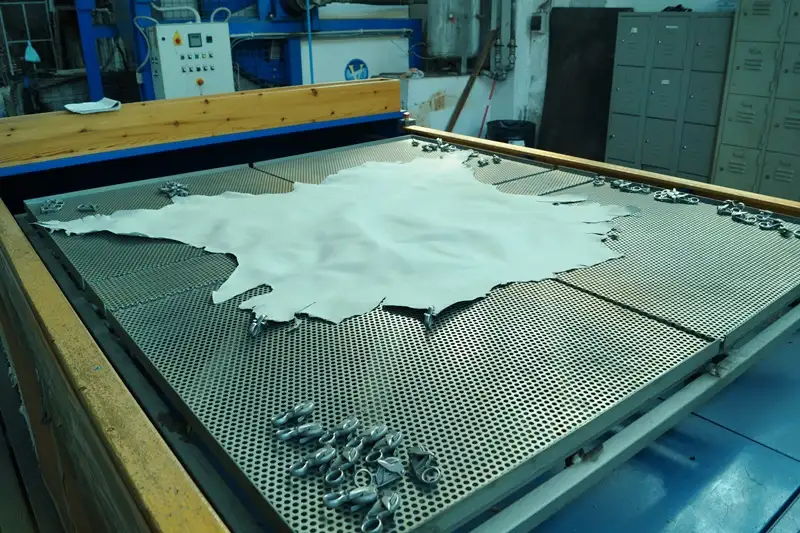

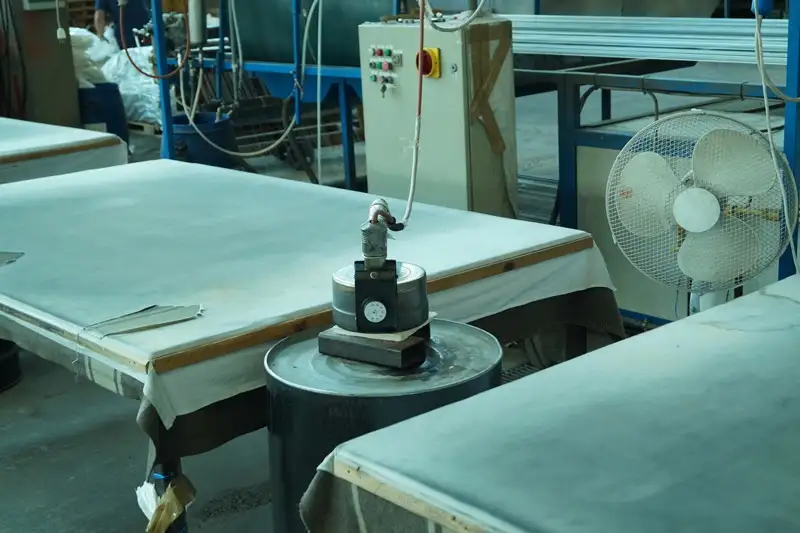

So, GVT has owned Ilcea since January and is slowly but surely building it back up. At the moment only half of the tannery is actually being utilized and that is the finishing part of it, always the most important side of it, even in shoes too. The first half of the process, the prepping of the leather for finishing is currently being handled at GVT’s tannery in Tuscany. When they have finished that process they ship the leather to Torino (where Ilcea is) in order to finish it off before sending to clients. It’s not an ideal situation but is what they have to do until GVT can inject some money to get that first half of the production going again in Torino. An off the head estimate is a few years before it’s all up and running as one tannery doing all.

I met with the production manager who was a very nice and knowledgeable man and who had been working for Ilcea for about 35 years, pretty much since he was out of high school (he is the one in the pics). I actually enjoyed talking to him as he debunked some myths that I had previously been under the spell of, such as: “leather is not as good as it used to be.” I asked him if leather in the past had less wrinkles in it and he almost laughed at me (not in a bad way but because it was kind of absurd and I kind of knew that too). He said that leather is the same today as it was 35 years ago but that the customers are the ones who have changed. The internet has made everyone an over qualified expert that brainwash others into believing that things are supposed to be a certain way, i.e. “Perfect” and that people in the past did not have these outrageously high expectations that they do today and in theory were a lot more realistic. This to me made sense as I constantly would ask myself, ‘why would leather be of less quality?’ and could not ever come to a rational explanation. Especially as we progress in technology and intelligence in doing things, it would only seem natural that leather should be getting better, not worse.

I also asked him if he felt that wrinkles in leather were considered a defect, and he said, ‘of course not!’ But he explained to me that there are two types of wrinkles, ones that are open and ones that are closed. One of them is able to be worked with and hide but the other is not and that is the defect, basically the wrinkles that have splits. But like I even I try to do when talking about leather, he related it to our own skin. We all buy calfskin to ensure the least amount of wrinkles. The younger the cow (like a human) the less likely they are going to age and have wrinkles. The older the cow gets, the more stressed etc. the more likely it will have wrinkles (just like humans). They are natural things. One cannot expect for leather to not have wrinkles. He felt that the expectation of wrinkle free was just absurd and I see where he is coming from. We as consumers only have our expectations about what we think is “right”, but little do we think about what is realistic.

The great thing about working with any company that has just been bought after a terrible tragedy (such as a ruined reputation) is that the new company will be eager to please their clients and will work hard to rebuild the reputation, ensuring that care is taken at each step. That idea alone, not to mention the leather is the reason that I personally am willing to spend more in the hopes to get better and more consistent leather. But more importantly are the people. For me, everything is about relationships. The better the relationship, the better business will be. But of course it’s always a two way street. One cannot take, take, take and never expect to give. And too often this is how it turns up. But meeting the people behind the new company and those in the tannery that worked for the old company (but actually cared about the brand and tannery itself) was quite refreshing as you could sense that they cared about the industry and what they were doing. And that gave me confidence, especially as I want to start a new relationship with these people.

It was a great time and quite an educational tour and I truly look forward to using their leather and building a fruitful relationship for both parties. Thank you to the Ilcea and GVT team for making this all possible.

P.S. here is a link to a video that shows a bit of the process:�http://www.gruppovecchiatoscana.com/dal-1957.htm

Sincerely,

Justin, “The Shoe Snob”

How fantastic and kind of you to share this. Getting good leather sources for the little brands and makers is about as easy as it is to spin gold from straw. I visited Prime tannery in USA which was eye opening. I hope your brand is able to use leather from here and become one of the ” big guys ”

Cheers,

Ritika

Very good and interesting article with a lot of details and good images! Thank you just for a nice reading! I’m looking forward to see you new products with perhaps both museum calf and their Cordovan lookalike.

Shoes in magazines are shown in pristine unworn condition (& flattering lighting), this raises unrealistic expectations. But it’ll be a brave company that shows how its products age over time in its marketing literature.

you are right…too much glossing over what is real, just like people in magazines….I like your 2nd sentence as it poses a challenge, one that I would be happy to attempt if I can manage to do it right

Fascinating report. I look forward to seeing their product used in your shoes. Can I look forward to some JF museum calf offerings down the road?

glad that you liked it Roger, and yes, more likely than not you can expect some, but more so on a exclusive type basis…not going to ride the train too hard you know

Great review Justin. Very informative. Thanks for all your hard work in disseminating this type of information.

Mel

thanks Mel!

Hi Justin.That was absolutely brilliant. Very informative, and one of your best!

hai justin thanks for the info.

The assertion that leather is as good as it used to be is highly debatable. The major problem is not the tanning or finishing, but rather the quality of the raw materials, i.e. the hides themselves. Remember that leather is a by-product of meat production. Over the past few decades, much ‘progress’ has been made in the breeding of faster growing and larger cattle, plus the use of antibiotics, etc. What this means is that the cattle grow faster, which affects the density and strength of their hides. In turn, this translates into lower quality leather.

The best tanneries may be able to source hides from more traditionally raised, heritage breeds of cattle, and hence perhaps they can make leather as good as ever. However, for the majority of leather out there, it is likely that it is lower quality than in the past.

If you ask long-time shoemakers if leather quality has declined, they will almost certainly say yes, and I don’t think that is simply a typical ‘the world is going to the dogs’ reaction.

There is also the simple fact that many traditionally great tanneries have closed (e.g. Freudenberg, perhaps considered the best of them all).

Thanks for your input. I suspect and believe that what you say is also true. I think that it is a bit of both to be honest. Leather quality has slightly (maybe more, I don’t know as I was not around 30 years ago) declined while consumer expectations has gone through the roof. I appreciate you sharing nonetheless and continue to enjoy your creations on SF.

thanks very much for this … very informative!

Brilliant and so much instructive 🙂

Justin, I am so very fascinated by your article here! I cannot tell you in words how grateful I am to you that you share this information, because it is in a way very personal, business and relation-building information. For me this was a real eye-opener, since you also talk about clients and their influence on what quality is even considered!!!!

I really love to think, that the general statement, that leather has become worst, is not true. I remember, that you sometimes have said so, and now I know the factors, why we think so. We expect more than realistic. We can get high quality. We, as costumers, have to know more than what we want, but, what is realistic to want. And we really need to see and listen. The cows themselves, this is an interesting discussion you have with shoefan: When you told me once in the Shoe-Care-fred, that leather is not so good any more, I have instantly thought about the meet-industry this is why I believed you. It is still a kind of prejudice, because it is not always true. You still can get good raw-skins. But this is a problem of production and peoples intentions, too. Since some years now, I only eat very good biologically made meat, and I eat fewer meat, too. This is what I can do.

But the feeling you give us in your article this is wonderful, the photos of this man that is so sympathetic, I would very much love to meet him, The Old Production Manager! You give us an impression, that everything has to be considered together, and it is really an enlightening information for me, that I as a client am part of the whole. I am grateful, that you are “blunt and brutally honest, [with] more outrageously demanding customers”

Yours, Giorgio from Berlin

Very enlightening! It’s always great to see more into the process and the work you and others put into the process.

this is an awesome post, glad the company is back. reputation that takes many years to build can be destroyed in an instant. as such, quality is paramount. love your blog

Hi Justin, thanks for the great article! Just wondering if you have any Italian vegetable tanned leather tannery(for handbag) to recommend? Your insights would be very helpful! Thanks a lot!

I have a Polish shoe maker that I would like to use. How can I purchase a few museum hides from Ilcea?

Any feedback would be greatly appreciated!